Kernel of Numerical Control is the core technology for AOTEK. Many tailored applications have been developed for a broad spectrum of machine types, from high production rate designs to small batch, very high precision machines.

Customization for special machines and processes

AOTEK can flexibly adapt the kernel of the CNC to specific user processes. Successful integrations have been done for a variety of machines, from high-speed, linear motor driven laser cutting machines to metal 3D printing machines, obviously comprising “standard” milling, turning and grinding machines.

Integration of customer applications and third party real time software modules. Hard real time software in operating systems (Windows, Linux, etc.)

The kernel can be made responsive to customer specific processes where feeds, speeds… depend on several conditions. This is especially relevant for optimization on different criteria like power, tool wearing, etc.

AOTEK’s mastering of hard real time software allows the integration of control algorithms at the same sampling rate than the CNC’s proprietary control loops and interfacing directly with the own kernel and associated PLC inputs and outputs. This is a very powerful feature that enables high end process control. AOTEK’s experience can support customers in using this techniques for applications like active damping, internal data monitoring, etc.

Support of serial, parallel and custom kinematics

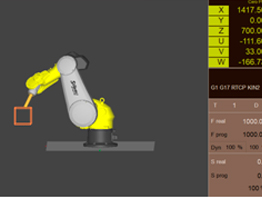

The flexible kernel architecture allows integration of any configuration of the machine axes. From standard serial kinematics as found in milling machines and robots to complex parallel kinematics. AOTEK’s experts have successfully integrate a broad range of configurations and can support OEMs in any design they implement.

Advanced, dynamics aware, path planning and High Speed Cutting (HSC)

AOTEK excels at the very complex problem of trajectory generation when commanded speed is high and program motions are small. Automatic filtering and path smoothing taking into account the axes dynamics while maintaining path fidelity is a quite difficult task that is performed by the kernel, reaching a good balance between program execution time, smoothness and precision. AOTEK supports customers in careful tuning of the HSC parameters for complex parts in five axis machining.